Diameter: 50 - 800mm

Length: 100 - 6000mm

Line count: 25 - 1500LPI

Coating performance: Hardness HV1300, porosity 1-2%

Circular runout: ≤0.01mm

Description of Anilox Rolls

Anilox roll is a laser-engraved, ceramic-coated metal cylinder that transfers a precise amount of ink, adhesive, or coating to a printing plate or directly to a substrate. The surface features tiny, cup-shaped cells that hold and deliver a measured volume of liquid to the printing process, ensuring consistent and uniform results. The line count (cells per inch) and cell volume are key specifications that determine the amount of liquid transferred and are chosen based on the printing application and substrate.

How Anilox Rolls Work

Ink/liquid transfer: Anilox roll is the "heart of the printing press/machine" because it precisely delivers ink, adhesive, or other liquids to the printing plate.

Cell structure: The surface of the anilox roll is etched with a pattern of tiny, engraved cells.

Controlled volume: These cells have a fixed volume and are designed to hold a precise amount of liquid or ink, which is then transferred to the printing plate.

Consistency: The structure of the anilox roll ensures consistent liquid or ink transfer, which is essential for high-quality and repeatable printing results.

Anilox Roll Specifications

Line Count (LPI): This measures the number of cells per linear inch or centimeter on the anilox roll's surface.

Cell Volume: The volume of the cells, measured in BCM (Billionths of a Cubic Meter), dictates the total amount of ink or liquid the roll can hold.

Engraving Geometry: Cells can be various shapes, such as hexagonal, quadrangular, or tri-helical, or open-channel designs, which affect ink transfer.

Anilox Roll Application

Flexographic Printing: The primary application for printing ink distribution onto printing plates.

Coating and Laminating: Applying precise layers of adhesives or coatings in manufacturing processes.

Corrugated Board Production: For gluing and coating during the manufacturing of corrugated sheets.

Anilox Roll Surface Treatment

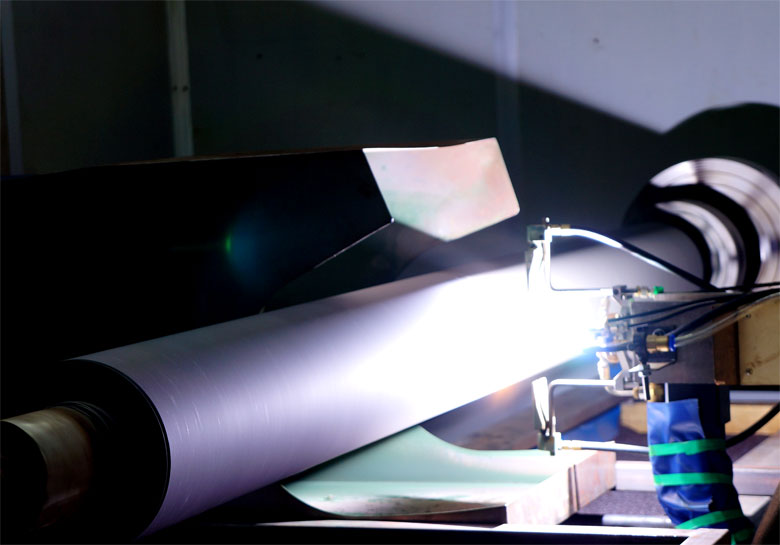

Perfect Coating: Advanced TriplexPro-210 three-cathode plasma spraying system imported from Switzerland, carefully selected pure imported Cr2O3 ceramic powder, It solidifies into a denser, harder, more wear-resistant and more suitable ceramic coating for laser engraving.

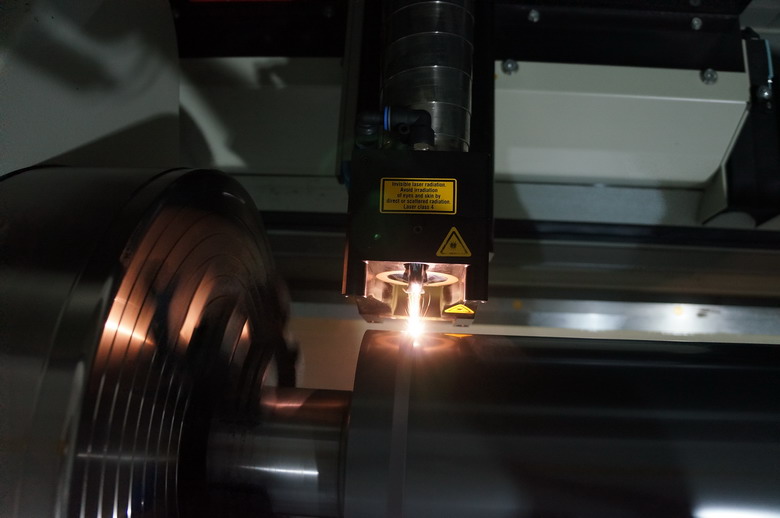

Precision engraving: We have introduced the new generation of fiber laser system and the new version of engraving software from Germany to engrave various mesh holes with finer quality, higher line count and greater ink carrying capacity, meeting any of your demands for ceramic anilox rolls.

Plasma spraying ceramic onto roller surface

Laser engraving on the roller surface

Grinding roller surface

can not be empty

The E-mail format is not correct

can not be empty