Diameter: 50 - 800mm

Length: 100 - 6000mm

Line count: 25 - 1500LPI

Coating performance: Hardness HV1300, porosity 1-2%

Circular runout: ≤0.01mm

Description of Corrugated Anilox Rolls

Corrugated anilox rolls known as the heart of print, the anilox rolls can make or break your corrugated box quality and customer satisfaction. Huatao anilox roll solutions have the precision and manufacturing quality for consistent and repeatable print applications with optimized color and ink usage.

Huatao offers a selection of anilox rolls for the flexo and corrugated packaging industry. Each anilox roll is tailored to specific production speeds, ink coverage, the substrate to be printed, and the complexity of the graphic image.

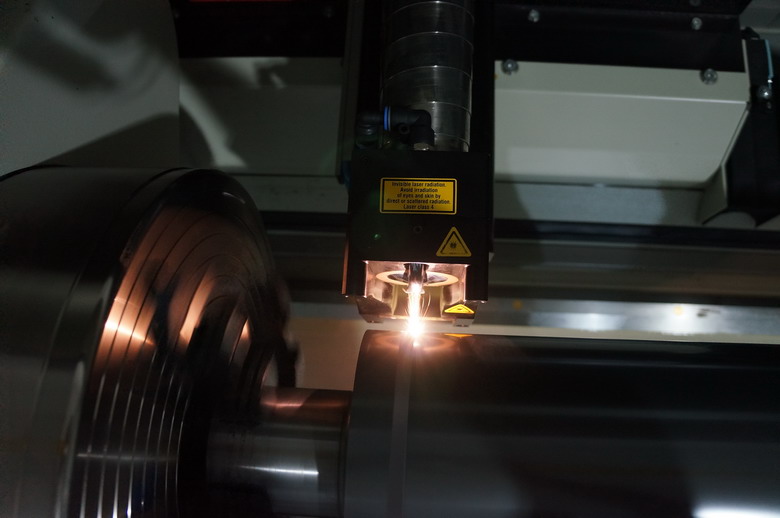

Precision laser technology guarantees accurate anilox cell geometry

Through advanced, multi-hit laser technology, the ink transfer and colour matching of Huatao anilox rolls remain as accurate as with the first order, even after many print jobs.

Huatao laser engraves the anilox roll cells to the highest screen resolutions and optimal cell volumes. This provides printers with an unlimited range of cell geometries for all graphic requirements.

Wear-resistant ceramic coating increases durability

Huatao pays a lot of attention to the coating of the anilox rolls. The high-quality ceramic coating results in a consistent, wear-resistant anilox surface, which withstands scratches and scoring from doctor blades. Besides, the ceramic coating increases corrosion resistance.

Construction of the anilox rolls

All basic rolls are made from the best quality steel, stainless steel, and aluminium. In addition, Huatao balances and tests each anilox cylinder separately. Certification guarantees high durability and optimal print quality throughout the entire lifespan of the anilox roll.

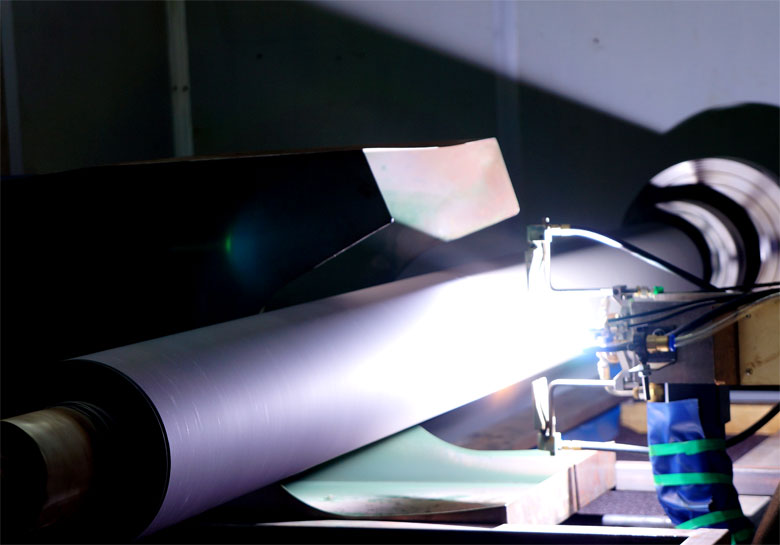

Plasma spraying ceramic onto roller surface

Laser engraving on the roller surface

Grinding roller surface

can not be empty

The E-mail format is not correct

can not be empty