Dimension φ110~450mmx L1600~ 3000mm

Temperature 50~420°C

Linear Pressure ; max 100kN/m

Surface Treatment : Hard-chrome plating / Teflon coating / Ceramic coating / Silicon rubber coating / Ceramic coating

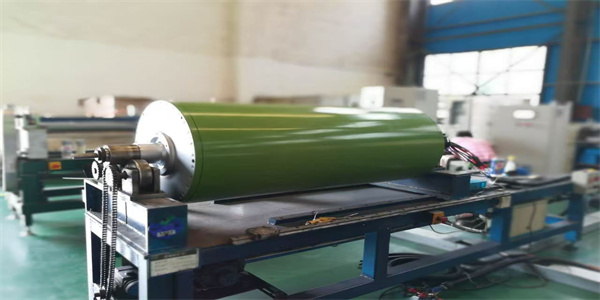

Description of Induction heating composite roller for Composite Material:

Composite materials and adhesives used in lamination require very precise temperature control.induction heating roller maintains high-precision surface temperature uniformity within±1℃ across a wide range of temperature.This enables perfect combining between such diverse materials as PET,PE,PP and other polymer films with aluminum foil,paper and iron sheets to produce a variety of composite materials.

Specification of Induction heating composite roller for Composite Material:

Dimension φ110~450mmx L1600~ 3000mm

Temperature 50~420°C

Linear Pressure ; max 100kN/m

Surface Treatment : Hard-chrome plating / Teflon coating / Ceramic coating / Silicon rubber coating / Ceramic coating

Main Application of Induction heating composite roller for Composite Material:

LCD panel

Aluminum plastic composite panel

Containers of food

Electronic parts materials(Printed circuit boards /lead frame

Plastic green houses and other agricultural/industrial materials

Food &Beverage cans

Materials of household electrical appliances as washing machines refrigerators,etc

Automobile Interior materials

Other packaging materials

can not be empty

The E-mail format is not correct

can not be empty